As the competition for smart devices becomes more and more fierce. Many manufacturers hope to highlight themselves through the differentiation of hardware and technology. There are different technology for touch screen display, in many cases, when we have not yet understood the new technology, new technology concepts have appeared in the market, such as the hot In-Cell and On-Touch market. Cell and OGS optical bonding technology, but do you know the difference?

01 Screen structure

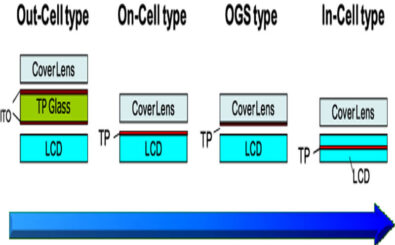

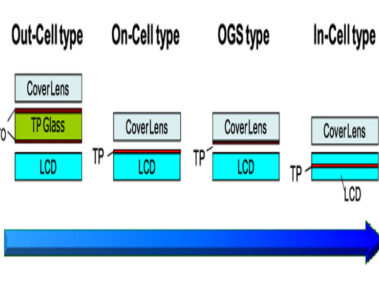

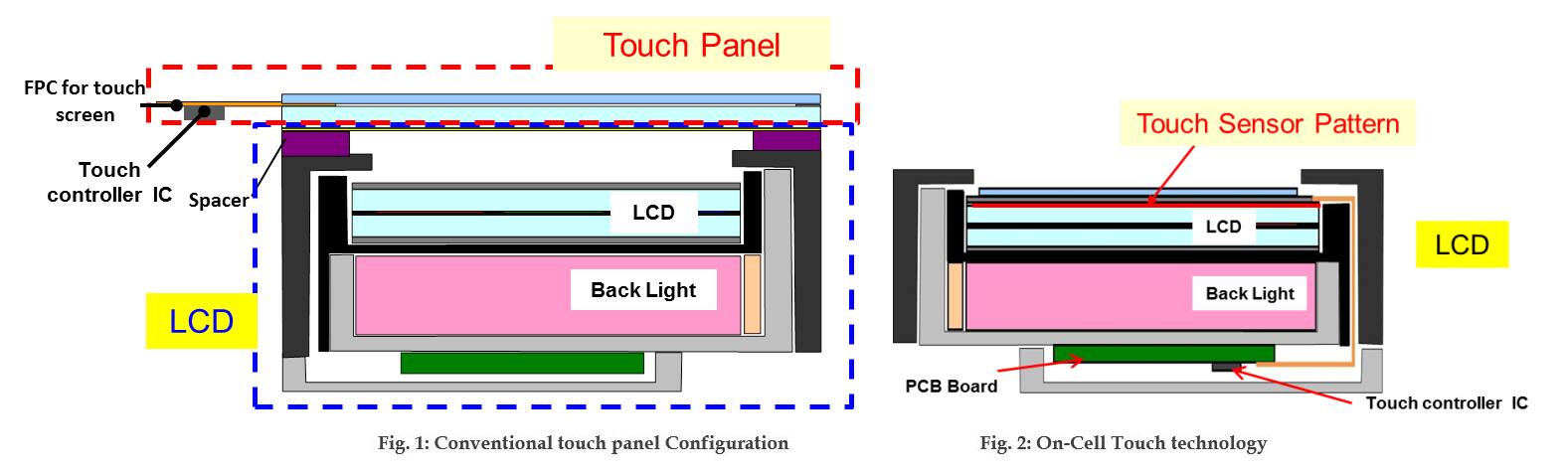

From the structure of the screen, we can roughly divide the touch screen display into three parts, from top to bottom are protective glass, touch screen, and display screen. These three parts need to be bonded. Generally speaking, two bondings are required, one bonding is performed between the protective glass and the touch screen, and the other bonding is between the display screen and the touch screen. According to the way of lamination, it can be divided into two types: full lamination and frame lamination.

02 Air bonding/tape bonding

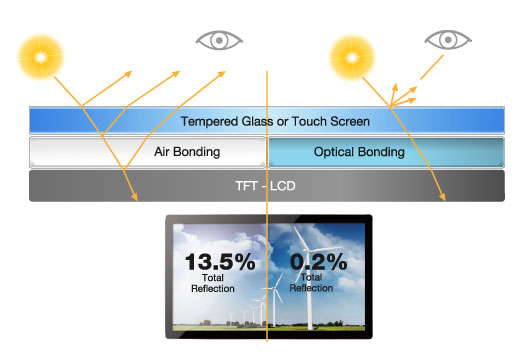

The so-called air bonding is also called tape bonding, that is, simply fix the touch screen and the four sides of the display with double-sided adhesive. This is also the bonding method adopted by most touch screen display at present. Its advantages are simple process and low cost. But because there is an air layer between the display and the touch screen, the display effect is greatly reduced after the light is refracted, which becomes the biggest shortcoming of the frame sticker.

Almost our touchscreen monitor use air bonding, like 10 inch touch screen panel, monitor touch screen 27.

03 Optical bonding

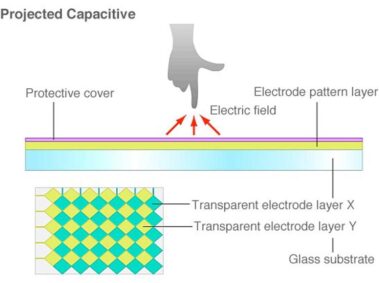

Optical bonding means that the panel and the touch screen are completely glued together with water glue or optical glue in a seamless manner. Compared with frame stickers, it can provide a better display effect. At present, the common fully bonded screens on the market are mainly OGS solutions led by original touch screen manufacturers, and On Cell and In Cell technical solutions led by panel manufacturers.

Optical bonding advantages: Full lamination technology cancels the air between the screens, which helps reduce the reflection between the display panel and the glass, which can make the screen look more transparent and enhance the display effect of the screen.

75% reduction in reflection of optical bonding

Another benefit of the optical bonding technology is that the screen will never get dusty. The touch module is also tightly integrated with the panel to increase the strength. In addition, the optical bonding can effectively reduce the noise caused by the display panel on the touch signal.

Interference. Although the advantage of full lamination is huge, the yield rate is relatively low. The consumption and scrap of the surface glass and even the panel during the lamination process caused by poor yield will inevitably lead to an increase in cost, so deaeration and The control of the bonding yield will become a more important factor than the material cost. Optical bonding widely using in outdoor digital signage, 10 inch monitor.

Optical bonding In-Cell/On-Cell/OGS

01 In-Cell

In-Cell refers to the method of embedding the touch panel function into the liquid crystal pixels, that is, embedding the touch sensor function inside the display screen, which can make the screen thinner and lighter. At the same time, the In-Cell screen must also be embedded with the supporting touch IC, otherwise it is easy to cause false touch sensing signals or excessive noise. Therefore, for any display panel manufacturer, the threshold for entering In-Cell/On-Cell touch screen technology is indeed quite high, and it is still necessary to overcome the difficulty of low yield. Because once the In-Cell is damaged, not only the touch screen will be lost, but the display will also be scrapped together. Therefore, manufacturers have higher requirements for In-Cell yield.

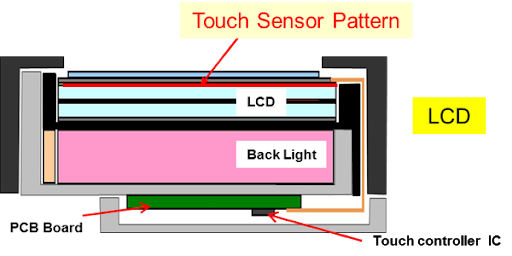

02 On-Cell

On Cell refers to the method of embedding the touch screen between the color filter substrate of the display screen and the polarizer. That is, the touch sensor is equipped on the liquid crystal panel, which is much less difficult than In Cell technology. Samsung, Hitachi, LG and other manufacturers have made rapid progress in On-Cell structure touch screens. At present, On Cell is mostly used in Samsung AMOLED panel products. Technically, it has not been able to overcome the problems of thinning and uneven color during touch.

03 OGS

OGS technology is to integrate the touch screen with the protective glass. The inner side of the protective glass is coated with an ITO conductive layer, and the coating and photoetching are directly performed on the protective glass. Because a piece of glass and one-time bonding are saved, the touch screen can do more Thin and lower cost. At present, domestic mobile phone brand manufacturers such as Tianyu Hornet 1st Generation, Gionee Fenghua, and Xiaomi 2 have all adopted OGS technology. However, OGS still faces the problems of strength and processing cost. Since the OGS protective glass and the touch screen are integrated, they usually need to be strengthened first, then coated, etched, and finally cut. In this way, cutting on strengthened glass is very troublesome, with high cost and low yield, and some capillary cracks are formed at the edge of the glass. These cracks reduce the strength of the glass. At present, insufficient strength has become an important factor restricting the development of OGS.